Cost-Effective Ceramic Coating Philadelphia Solutions for Luxurious Coatings

How Ceramic Covering Offers Resilient Protection Against the Elements

Ceramic finishing has become an awesome remedy for securing surface areas against diverse ecological obstacles. By producing a resilient, chemically bound layer, it not just improves visual allure however additionally provides defense from UV rays, extreme temperatures, and chemical stains. The hydrophobic attributes of ceramic layer better add to its efficacy by fending off water and lessening dirt build-up. Recognizing the complete scope of its benefits and exactly how it contrasts to traditional protective approaches raises essential inquiries about long-term upkeep and efficiency. What ramifications do these elements hold for numerous applications?

What Is Ceramic Finish?

Ceramic layer is a sophisticated safety service that enhances the durability and appearance of surfaces, particularly in vehicle applications. This innovative technology consists of a liquid polymer that chemically bonds with the factory paint of an automobile, creating a protective layer that is dramatically more durable than typical wax or sealers.

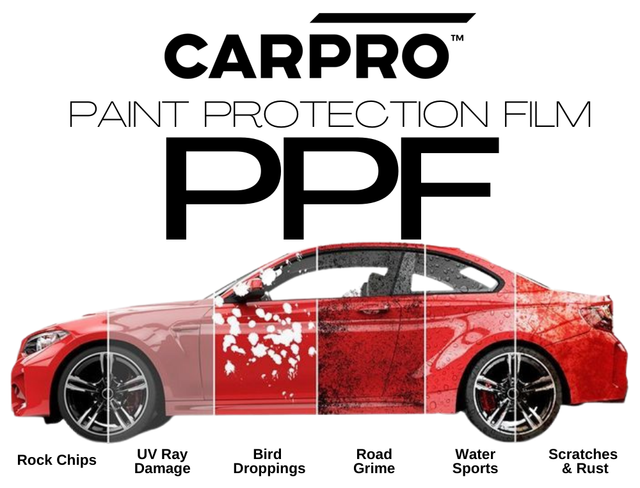

Designed to provide resilient protection against environmental impurities, ceramic finishings are immune to UV rays, chemical spots, and small abrasions. This defense helps preserve the lorry's aesthetic appeal gradually, avoiding oxidation and fading that can result from extended direct exposure to the elements.

Additionally, ceramic coverings are hydrophobic, meaning they repel water and other fluids, which assists in the avoidance of dirt and grime build-up. This building not just makes cleaning easier however likewise adds to keeping the lorry's luster.

Available in numerous formulas, ceramic coverings can satisfy different surface area products, consisting of glass and steel, increasing their applicability past simply auto usages. In general, the fostering of ceramic finish modern technology stands for a substantial innovation in surface area defense, supplying a reliable option for those looking for to protect the stability and appearance of their financial investments.

Exactly How Ceramic Layer Works

The effectiveness of ceramic finishing hinges on its special chemical composition and application procedure. Made up mostly of silica (SiO2) and other sophisticated polymers, ceramic layers create a molecular bond with the surface area of the product they are put on, normally auto paint. This bond develops a semi-permanent layer that serves as a barrier versus environmental contaminants.

Once used, the finishing goes through a treating procedure, which can take numerous hours to days, depending on environmental conditions. As it treatments, the layer sets and comes to be hydrophobic, implying it drives away water and other materials.

Advantages of Ceramic Layer

Offering a wide variety of benefits, ceramic coating functions as an exceptional option for surface area defense. One of its primary benefits is its longevity, supplying a durable barrier versus ecological contaminants such as dirt, UV rays, and chemical exposure. This resilience considerably prolongs the life expectancy of the surface areas it protects, minimizing the need for constant repair work or substitutes.

In addition, ceramic coatings enhance aesthetic appeals by imparting a shiny surface that keeps its luster gradually. The hydrophobic residential properties of these layers repel water, making it easier to clean surfaces and lessening the build-up of crud. This self-cleaning characteristic not only saves time yet additionally boosts the surface's total look.

Additionally, ceramic coatings supply resistance to scrapes and small abrasions, safeguarding the honesty of the underlying materials. This is specifically valuable for auto applications, where keeping an immaculate exterior is necessary for resale value.

Comparing Ceramic Covering to Typical Techniques

Regularly, individuals look for effective remedies for surface area protection, prompting a contrast in between conventional methods and ceramic layers such as wax or sealants. Traditional choices like wax give a momentary layer of protection, usually lasting a couple of weeks to a number of months, relying on environmental conditions and lorry use. While wax can enhance sparkle and offer an obstacle against impurities, its performance decreases promptly, requiring constant reapplication.

In contrast, ceramic finishes supply a more durable service, creating a solid, chemically bonded layer that can sustain for several years. This resilient protection considerably decreases the demand for normal maintenance, enabling lorry owners to take pleasure in a continually sleek appearance without the hassle of regular applications. Ceramic layers are also a lot more resistant to UV rays, chemicals, and physical abrasions, hence offering premium defense against the components.

While traditional techniques may be extra available and less costly initially, the durability and efficiency of ceramic layers present a compelling situation for those seeking extensive surface area protection. Ultimately, the selection in between ceramic coatings and conventional methods depends on individual priorities, such as time, budget, and desired level of protection.

Upkeep Tips for Durability

Recognizing the distinctions in between traditional approaches and ceramic coatings highlights the importance of proper maintenance to make best use of the long life of ceramic layers. Ceramic Coating Philadelphia. To make certain the performance of ceramic finishings, regular care is official statement necessary

First, always wash the layered surface area with pH-balanced cars and check it out truck hair shampoos. Prevent severe chemicals or abrasive materials, as they can degrade the covering. A gentle hand clean with microfiber towels lessens the danger of scratches.

Second, think about using a maintenance spray developed specifically for ceramic layers. Ceramic Coating Philadelphia. This can boost hydrophobic residential properties and add a layer of security, making certain the covering remains effective with time

Third, prevent automatic auto washes that use brushes, as they can wear down the covering. Rather, select touchless washes or hand cleaning whenever possible.

Last like it but not least, routine assessments for any indicators of damage or wear are critical. Attending to issues quickly can protect against extra substantial damages and maintain the layer's stability.

Verdict

In summary, ceramic finishing uses a powerful solution for shielding surfaces from environmental obstacles. By comparing it to conventional protective techniques, the prevalence of ceramic finishing ends up being apparent, making it a preferred option for resilient surface area defense.

Recognizing just how ceramic coatings work is essential in valuing their function in surface area protection.

Offering a wide variety of advantages, ceramic covering offers as an outstanding option for surface protection.Regularly, people seek effective remedies for surface protection, motivating a contrast between standard approaches and ceramic coverings such as wax or sealers.In summary, ceramic layer offers an awesome remedy for shielding surface areas from environmental difficulties. By contrasting it to standard protective approaches, the supremacy of ceramic finishing comes to be noticeable, making it a favored option for long-lasting surface area protection.